wad to window… part 3

The story behind a specially commissioned set of handwoven

curtains - crafted from plant dyed hand spun Siroua wool.

join us as we tell the story of the creation of the cloth for the project - we visit the Wad (River) in the High Atlas, where the wool is washed and hand spun by local Amazigh women, meet the dyer, who uses his skills to create subtle shades using this ancient dye, the weaver of the cloth and finally the making up of the curtains for our discerning client.

PREPARING THE LOOM FOR WEAVING THE CLOTH

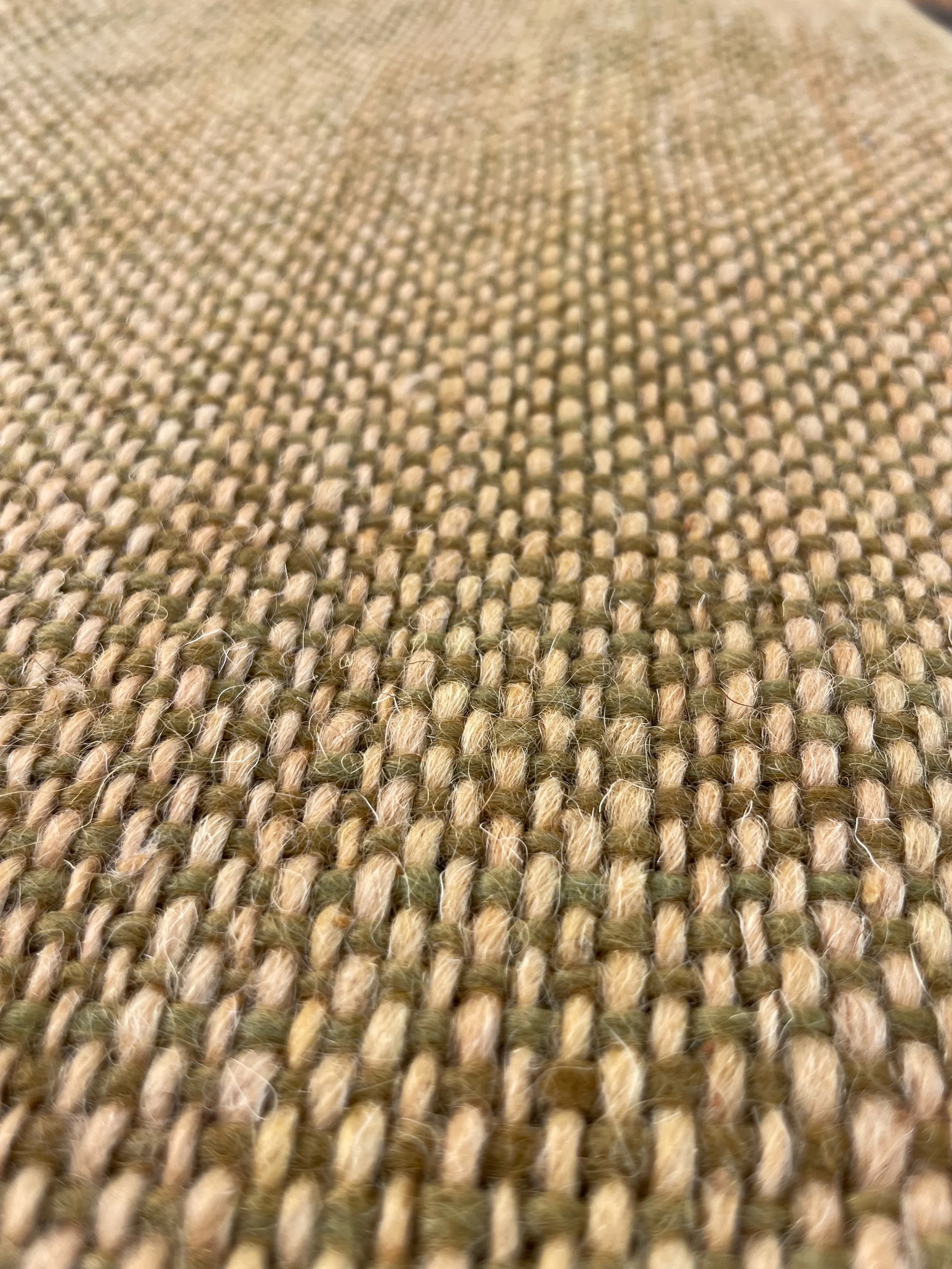

The first thing the weaver needs to do is create the warp (the long threads that run vertically through the weave). This is done on a circular ‘warping mill’ to create the warp using the green shade, 440 warp ends x approx 12m - that’s a lot of wool!

The master weaver we work with has years of experience working with wool, creating blankets and large width pieces of cloth. Although he does not usually work with this thickness of wool in the warp, his tacit knowledge ensured that the task of creating this cloth was done with patience and precision, resulting in a beautiful end product.

THE WEAVE PROCESS

After winding on the warp and threading up the loom, Master weaver (Ma’alam) Abdherrahim works with his assistant, Mohammed to weave the cloth, sending the shuttle back and forth across the warp to create the weft (the horizontal part of the cloth). Once the desired length of cloth has been woven, the cloth is cut off the loom, ready for finishing.

FINISHING THE CLOTH

After collecting the cloth from the weaver, we carefully check through the cloth for any burrs, impurities in the wool or any small weave errors, pressing the cloth as we go, then fold and pack it ready for delivery to the curtain maker.

metres and metres of beautifully hand woven, hand dyed 100% wool cloth.

Slow textiles with a touch of the hand